How many types of automatic tool changers for CNC machine tools are you familiar with?

Category:

Industry News

Author:

Source:

Published Time:

2021-08-30

In order to complete multiple machining processes in a single workpiece clamping, shorten auxiliary time, and reduce errors caused by multiple workpiece installations, CNC machine tools must be equipped with an automatic tool changer. The automatic tool changer should meet the basic requirements of short tool changing time, high tool repositioning accuracy, sufficient tool storage capacity, small footprint of the tool magazine, and safety and reliability.

I. Types of Automatic Tool Changers

1. Rotary turret tool change

A rotary turret is the simplest type of automatic tool changer, commonly used in CNC lathes. It can be designed in various forms, such as a four-sided turret, a six-sided turret, or a disc-type axial tool mounting turret. Four, six, or more tools are mounted on the rotary turret and changed according to the instructions of the CNC device.

The rotary turret must have good strength and rigidity in its structure to withstand the cutting resistance during rough machining. Since the machining accuracy largely depends on the tool tip position, for CNC lathes, the tool position is not manually adjusted during processing, so it is even more necessary to choose a reliable positioning scheme and reasonable positioning structure to ensure that the rotary turret has the highest possible repeat positioning accuracy (generally 0.001~0.005mm) after each repositioning.

Generally, the tool changing action of a rotary turret includes lifting the turret, repositioning the turret, and clamping the turret.

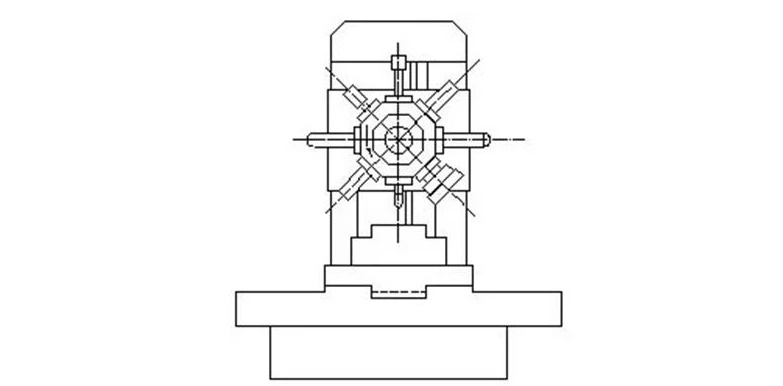

2. Tool change by changing the spindle head (tool rotation as the main movement)

Changing the spindle for tool change is a relatively simple tool changing method for CNC machine tools with rotating tools. This spindle head is actually a turret tool magazine, as shown in the figure.

Spindle heads come in horizontal and vertical types. Usually, the turret is repositioned to change the spindle head to achieve automatic tool changing. Various tools needed for each process are pre-installed on the various spindles of the turret. When a tool change command is issued, the spindle heads are sequentially rotated to the machining position, and the main movement is connected to allow the corresponding spindle to drive the tool to rotate. Other spindles in non-machining positions are disengaged from the main movement.

This type of spindle change tool changer eliminates a series of complex operations such as automatic loosening, clamping, unloading, loading, and tool handling, thus shortening the tool changing time and improving the reliability of tool changing. However, due to space limitations, the size of the spindle components cannot be too large, which affects the rigidity of the spindle system. To ensure the rigidity of the spindle, the number of spindles must be limited, otherwise the structural size will increase. Therefore, turret spindle heads are usually only suitable for machine tools with fewer processes and lower precision requirements, such as CNC drilling and milling machines.

3. Automatic tool changing system with tool magazine

Since the number of tools that can be accommodated by rotary turrets and turret-type tool changers is limited and cannot meet the needs of complex part processing, most automatic tool changing CNC machine tools use automatic tool changing devices with tool magazines. Automatic tool changing devices with tool magazines consist of a tool magazine and a tool changing mechanism, and the tool changing process is more complex. First, all the tools used in the processing process are installed on standard tool holders, pre-adjusted in size outside the machine, and then placed in the tool magazine in a certain way. When changing tools, first select the tool in the tool magazine, then the tool changing device removes the tool from the tool magazine or spindle, exchanges it, inserts the new tool into the spindle, and returns the old tool to the tool magazine. The tool magazine has a large capacity and can be installed on the side or top of the headstock. Since the headstock of the CNC machine tool with an automatic tool changing device with a tool magazine has only one spindle, the rigidity of the spindle component must be high to meet the requirements of precision machining.

In addition, the tool magazine has a large number of tools, so it can perform multi-process machining of complex parts, greatly improving the adaptability and machining efficiency of the machine tool. Automatic tool changing systems with tool magazines are suitable for CNC drilling centers and machining centers.

II. Tool Magazine and Tool Selection Methods

1. Tool magazine types

The function of the tool magazine is to store a certain number of tools and exchange them with the tools on the spindle through a robotic arm. There are many types of tool magazines, such as disc-type tool magazines and chain-type tool magazines. The type and capacity of the tool magazine should be determined according to the process range of the machine tool. In the disc-type tool magazine shown in Figure 7-16, the direction of the tool is the same as that of the spindle. When changing tools, the headstock rises to a certain position so that the tool on the spindle is aligned with the bottom position of the tool magazine. The tool is clamped, and under the control of the CNC, the spindle releases the tool holder. The disc-type tool magazine moves forward, pulls out the tool on the spindle, and then rotates the next tool needed for the process to align with the spindle. The tool magazine retracts to insert the new tool into the spindle hole, the spindle clamps the tool holder, the headstock descends to the working position, the tool change task is completed, and the next process is machined. The advantages of this tool changer are simple structure, low cost, and good tool changing reliability; the disadvantages are long tool changing time, suitable for machining centers with small tool magazine capacity.

For machining centers that require a larger tool magazine capacity, a chain-type tool magazine (Figure 7-17) can be used. The chain-type tool magazine has a compact structure and a large tool magazine capacity. The shape of the chain link can be made into various shapes according to the layout of the machine tool, and the tool changing position can also be highlighted for easy tool changing. When it is necessary to increase the number of tools, only the length of the chain needs to be increased, which brings convenience to the design and manufacturing of the tool magazine.

2. Tool selection methods

Generally, there are multiple tools stored in the tool magazine. Before each tool change, tool selection is required. The commonly used tool selection methods include sequential tool selection and random tool selection. Sequential tool selection is to insert the tools required for processing the workpiece into the tool magazine sleeves in order according to the process requirements before processing, and the tools are adjusted sequentially during processing. When processing different workpieces, the tool order in the tool magazine must be readjusted. Its advantage is that the drive and control of the tool magazine are relatively simple. Therefore, this method is suitable for automatic tool changing of medium and small CNC machine tools with large batch size and small number of workpiece types.

With the development of CNC systems, most CNC systems currently use random tool selection, which is divided into three types: tool sleeve coding, tool coding, and memory type.

3. Tool coding methods

Tool coding or tool sleeve coding requires the installation of identification coding bars on the tools or tool sleeves, generally based on the principle of binary coding. The tool coding tool selection method uses a special tool holder structure and codes each tool. Each tool has its own code, so the tool can be reused multiple times in different processes, and the removed tool does not need to be returned to the original tool seat, and the capacity of the tool magazine can be reduced accordingly.

However, each tool is equipped with a dedicated coding ring. Longer tools are more difficult to manufacture, and the tool magazine and robotic arm structures become more complex. The tool coding method is such that one tool corresponds to only one tool holder; a tool removed from a holder must be returned to the same holder, making tool retrieval and placement cumbersome and increasing tool change time. Currently, memory-based methods are widely used on machining centers. This method allows the tool number and the tool holder position in the tool magazine to be stored in the PLC of the CNC system. Regardless of which tool holder the tool is placed in, the tool information is always stored in the PLC. The tool magazine is equipped with a position detection device to obtain the position information of each tool holder. This allows tools to be removed and returned arbitrarily. The tool magazine also has a mechanical origin point, allowing for the nearest tool selection each time a tool is selected.

III. Tool Changing Device

In the automatic tool changing device of a CNC machine tool, the device that implements the transfer and loading and unloading of tools between the tool magazine and the machine spindle is called a tool changing device. There are two methods for tool changing: tool changing is achieved by the relative movement of the tool magazine and the machine spindle, and tool changing is achieved using a robotic arm. The device that uses the relative movement of the tool magazine and the machine spindle to achieve tool changing must first return the used tool to the tool magazine before taking out a new tool from the tool magazine. The two actions cannot be performed simultaneously, resulting in a longer tool change time.

The robotic arm tool changing device, however, can simultaneously grasp and load and unload tools from the machine spindle and the tool magazine during tool changing, thus further shortening the tool change time. The method of using a robotic arm for tool changing is the most widely used. This is because robotic arm tool changing is flexible, fast, and simple in structure. The robotic arm can perform a series of actions such as grasping the tool, pulling out the tool, rotating, inserting the tool, and returning. To prevent the tool from falling, the active claws of the robotic arm are equipped with a self-locking mechanism.

Keywords:

2021-05-25